Feature Engineering & Process Fault Detection

|

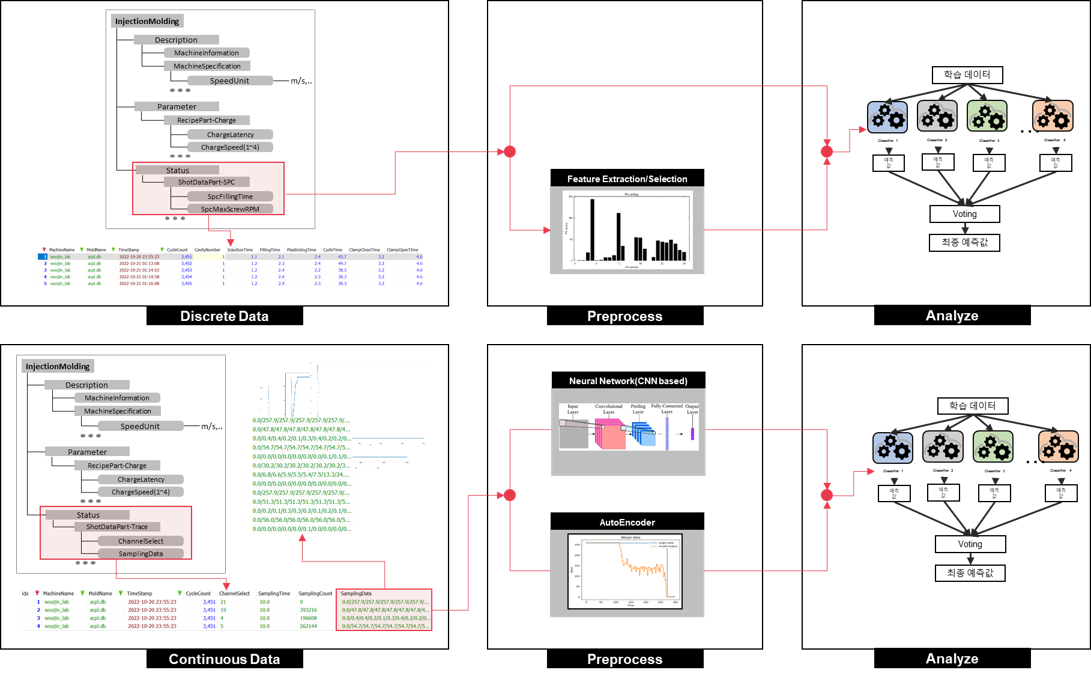

The process of gathering data for tasks like failure analysis or anomaly detection in contemporary manufacturing procedures is becoming exceedingly intricate and voluminous. While the quantity of data plays a crucial role in enhancing the precision of a system's predictive maintenance, complicated data can lead to issues such as escalated analytical costs and decreasing model performance. Various feature selection and extraction methods have been explored to mitigate this issue.

These methods involve extracting features using cutting-edge time series data and statistical values. However, for predictive maintenance procedures, it’s necessary to take into account data attributes from domain knowledge that extend beyond these features. FI LAB is conducting research on feature engineering that effectively leverages the unique aspects of these process situations and applies the insights gained from both experience and theoretical knowledge in its analyses. |